Description

The DPF300 is a manual depaneling system is designed to solve the needs of depanelizing (PCB Nibbler) small PCB's, FR4 type materials. It can also be used on aluminium substrate PCB's.

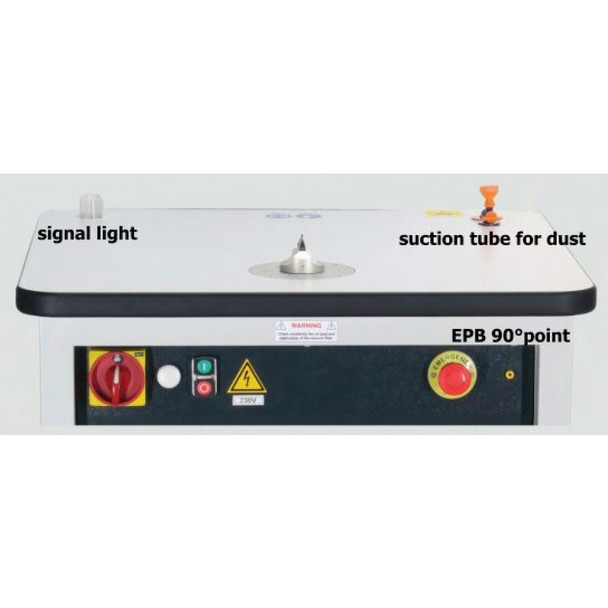

- ESD table with EPB 90°

- ESD zinc coated steel frontal feet and rear turning wheels with brake Ø80.

- Easy Change PCB guides and milling bits for different routed widths.

- Designed to solve problems due to stress, break or tearing out of PCB’s fibres that often occurs using standard blades or manual tools

- The vacuum system allows you to place the system easily and quickly in any working area, without mess.

- Interchangeable guide in hardened and tempered steel. Standard thickness: 1.0 - 3.0mm (SEE MORE)

- Milling cutters for hard metal with specific geometry for FR4, CE and M. Standard diameters: 1.0 - 3.0mm (SEE MORE)

- Milling cutters for Aluminium. Standard diameters: 1.0 - 3.0mm (SEE MORE)

- Other spares are available here (SEE MORE)

- Electrical micro spindle speed: max 24000 rpm.

- Vibrations: < 2,5 m/s2 - Acoustic pressure level : 80db (A), (+/-3db) measured at operator’s site

- Dimensions : 64x 70x 95(H) cm - Weight: 73 kg

- Voltage: 230V/50Hz - power: 0.90Kw

- Depression: 28 kPa (-280 mBar)

- Max PCB’s thickness: max 4.0mm

- Slot length (L): min. 11mm

- Slot width (V): for a standard guide 1.0 - 3.0mm (tolerance 0 / - 0.02 mm)

- Isthmus distance from components (C): min. 1 mm - PCB materials: FR4 – CEM – ALUMINIUM (for aluminium special milling cutters are needed)

- CE Marked

Information sheets

Video

Product Reviews

Delivery & Returns

DELIVERY

All orders received by us are shipped subject to availability.

For the majority of our products, carriage charges are calculated at a flat rate charge. Certain products are marked as having special carriage requirements due to size, weight or contents. This is highlighted on the product information and basket pages.

The described delivery estimates for our selection of shipping options is the time for delivery having been dispatched from Grove Sales Ltd. This excludes our internal processing, picking and packaging time.

Shortages or damage sustained during transit must be notified to both the carriers and ourselves within three days of receipt of goods. In the event of a non-delivery, we must be notified immediately after the invoice is received, otherwise no liability can be accepted.

We reserve the right to ship products at a later date (up to 28 days after purchase) where the product ordered is not in stock at the time of purchase. In this situation you will be contacted and offered a full refund instead of delivery of the product.

We cannot be held responsible for disruption to shipping caused by industrial disputes or action outside our direct control. If such disruption occurs you will be offered delivery via an alternative delivery or fulfillment company or a full refund.

FREE Delivery Promotions

Our Free Delivery promotion is subject to change or removal without notification. It is only available for orders within the UK. Any delivery address may only take advantage of the free delivery promotion on a single user account.

RETURNS

All returns to Grove Sales Ltd must be approved in advance.

All goods being returned must be accompanied by a returns number which can be obtained by calling our Sales Team on 01202 588900 to arrange the necessary return.

Unwanted goods may be returned within 30 calendar days of purchase providing, the goods must be unused and ‘as new’ and returned in their original packaging wherever possible. This should include all product boxes, all manuals and accessories, and returned in excellent condition.

15% will be deducted from the credit note as a restocking fee unless the return is due to faulty products or errors caused by Grove Sales Ltd.

We are unable to accept returns on custom made products.

If goods are found to be faulty and within warranty period, Grove Sales Ltd will issue you either a new product once evaluated, or a repair by the manufacturer.

Shipping

You will be responsible for the return of unwanted goods and the cost of carriage.

Your Rights

This returns policy does not affect your statutory or legal rights.

Contact Us

If you need more information please call our Sales Team on 01202 588900

Instruction Manual

Instruction Manual